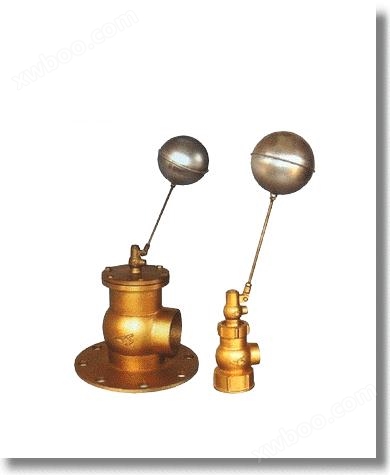

Copper float ball valve

Copper float ball valves are developed using domestic and foreign technologies, with quality indicators such as wear resistance, pressure resistance,

Product details

|

|

|

The copper floating ball valve body adopts copper die-casting technology, which ensures excellent coordination between various components without corrosion, loosening or clamping, ensuring stable operation of the ball valve for a long time. At the same time, the stainless steel component design ensures that the ball valve works in high humidity environments without chemical corrosion reactions, making the drinking water pure and healthy.

Concept of lever mechanicsThis product features a unique lever type rod buoyancy transmission, which increases the buoyancy transmission of the sphere by multiple times. The sealing pressure can reach over 6kg, significantly higher than the national standard of 6kg sealing pressure. And in conjunction with the stable transmission of the vertical valve core, it comprehensively solves the problem of failure of the floating ball valve due to unbalanced force on the valve core, ensuring the reliability of the floating ball valve operation.

Equipped with liquid level adjustment function

In order to enable consumers to easily control the liquid level height of the water tank without changing the pipeline configuration, this product has specially improved the float ball connecting rod form and added a liquid level adjustment gear rod group, so that the liquid level of the water tank can be adjusted freely within the length range of the adjustment rod to meet the needs of different situations.

|

Specification and valve diameter (d) |

15(1/2) |

|

Float diameter (D) |

Φ114 |

|

Total length of ball valve (installation) (L) |

420 |

Online inquiry